Hacıoğlu Steel & Construction

Turnkey Trust, Quality and Engineering

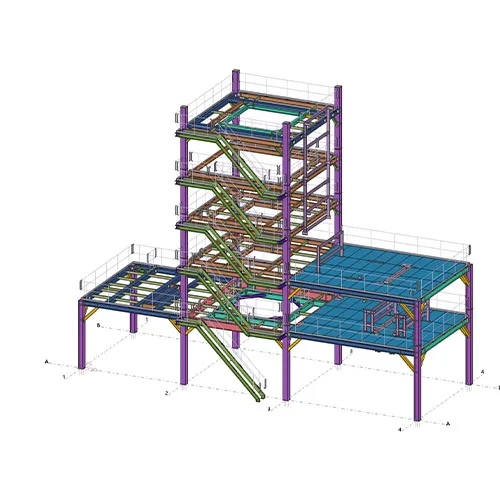

As Hacıoğlu Steel, we offer turnkey solutions covering steel construction, project design, manufacturing, and assembly processes. We provide services in a wide range of fields from industrial structures to bridges, from special platforms to market areas, completing each project with engineering discipline and aesthetic understanding.

With our team of experts, we build not only steel structures but also trust, quality, and sustainable success. Timely delivery, maximum customer satisfaction, and compliance with international standards are the cornerstones of our work.

We are by your side on the journey of an idea transforming into steel.

Fields

Industrial Buildings

Covered Marketplaces

Bridges

Mezzanines

Machine Platforms

Cold Storage

Villa

Fire Escapes

Sports Facilities

Shopping Centers

Services

It all ends on the Drawing Table.

With our experienced team of civil engineers, we provide comprehensive project services.

- We offer static calculations, architectural and structural project design, drafting, and consultancy services for all types of structures.

- A suitable structural system is selected in accordance with the architectural design of the building. Following static analysis, alternative systems are evaluated and the most appropriate one is chosen.

- Once the structural system is determined, the structural analysis is conducted. Special loads acting on the structure and service loads defined by the regulations are taken into account. Additionally, extra loads such as earthquakes, snow loads, and wind loads are included in the static calculations. Based on these calculations, the appropriate steel profiles to be used are determined. The connections between structural elements—such as welds and bolts—are also calculated. The results of these calculations are then detailed in structural drawings. General views of the building, plans and sections, and typical/detail sheets of the connection points are prepared. Upon request, steel construction manufacturing drawings can also be provided once the structural design is completed.

Our Guarantee of Quality Manufacturing

Steel Construction Manufacturing Stages:

- Work Preparation: The production plan is created by determining which parts will be produced on which machines.

- Sheet Cutting: Waste-free cutting is performed on CNC plasma cutting machines.

- Profile Processing: Steel profiles are processed through various machines (cutting, drilling, etc.).

- Marking and Assembly: Each part is assigned a position number, and after quality control, components are assembled according to the technical drawings.

- Welding: All surfaces are cleaned, the proper welding bevels are prepared, and welding is carried out.

- Sandblasting and Painting: After surface preparation, paint is applied in the desired color and thickness.

- Corrosion Protection: Steel elements are protected using methods such as sandblasting, galvanizing, and chemical cleaning.

Professional Execution with Our Experienced Team

We provide turnkey contracting services as the main contractor in all stages of design, manufacturing, and assembly.

- Our company, which is not only experienced in steel construction manufacturing but also highly professional in assembly, offers services both domestically and internationally.

- After the necessary preparations are made at the construction site, steel components manufactured in our factory are transported to the site. Once on-site, all safety precautions are taken and the assembly process begins.

- Since the steel structure is assembled and supervised on-site by professional teams, major errors in implementation are prevented.

You can contact our project office to receive detailed information about the structural steel design of your project or to request a quotation.